Greenwood, Montana

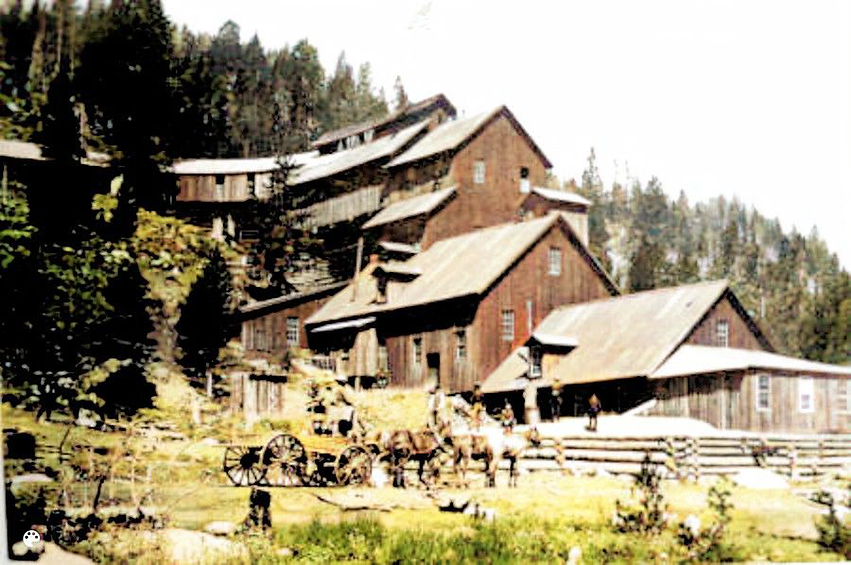

At the annual meeting of the Hecla Consolidated Mining Company in January of 1882, and not satisfied with the great work, Henry Knippenberg had accomplished in his first year as General Manager, he asked the board for the go-ahead to build a concentrator needed to process second-class ore which was piling up on the dumps. There were estimated to be about 40-50 thousand tons awaiting processing. On June 10 1882, work began erecting the large 150-ton concentrator at Greenwood. The concentrator had a telephone line that connected Glendale to Greenwood and Hecla. The Company had its sawmill and all the timbers and lumber were sawed on the ground, costing about 10 dollars per 1,000 feet.

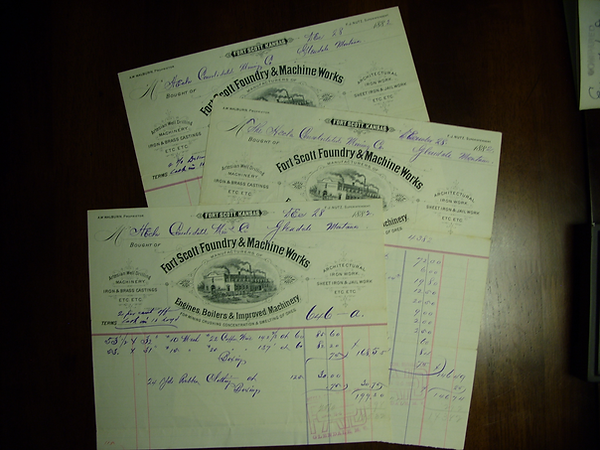

The concentrator, which was a marvel of efficiency, treated about 100 tons every twenty-four hours and treated 177,092 tons of second-class ore between 1882 to 1898. The machinery was supplied by Fort Scott Machine Company, of Fort Scott, Kansas. During 1883, 1884, and 1885, this plant had been supplied with 37,000 tons of second-class ore ultimately furnishing the smelter at Glendale with nearly 7,000 tons of concentrates. Upon completion of the mill and three-mile T-rail tramway from Hecla to Greenwood and a water flume nearly one mile long. The net cost was about 76,000. Despite the cost of this improvement, the shareholders continued to receive their dividend checks.

%20copyvb_edited.jpg)

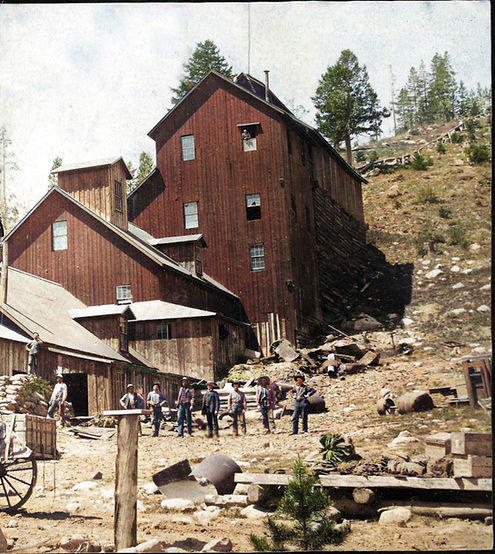

The concentrator ran off water power supplied by a water flume from Trapper Creek about one half mile with a vertical drop of two hundred feet processing low grade ore. A tramway was built to move ore between Hecla and Greenwood which measured about four miles in length. There were three cars, each with a brakeman which constituted a train and the empties were pulled back to the ore house at the base of Lion Mountain by Mules/horses. The Grade was steep and when the heavily loaded cars were in motion, they occasionally jumped the track causing injury and sometimes killing the brakemen. One such death occurred in April 1883 when two men, Joe Baker and Sherman Vance lost control of the cars and Joe Baker was killed from the impact of his body hitting trees after being ejected from the ore cars. It is not clear if the only survivor, Sherman Vance filed a lawsuit as the newspapers alluded that he might.

In a newspaper article dated (September 1,1882),“The Management of Greenwood, the Hecla Company’s new town, will prevent the erection of any saloon buildings within the sacred precincts of that village. The principal office of the company is to be erected in Greenwood. On November 2nd, 1882, his daughter, Miss Mamie opened the water wheel and set the machinery in motion.

Henry Knippenberg to the "Mining Record" New York City: November 8, 1882

Hecla Consolidated Mining Co. Glendale, M.T.

On the 2nd of November the "Big Concentrator" at Greenwood was set in motion, the power being turned on by Genl. Manager Knippenberg's little 10 year old daughter, Miss Mamie Norwood Knippenberg amid the glad shouts of workmen & visitors. By her side stood the happy father and mother and Supt. Parfet and Prof. Fred De Stivolinska of Fort Scott, Kansas, the designer of the plant. The works will be run empty. In 1883, Knippenberg would name one of the mines on Lion Mountain, "Mamie" after his daughter and Superintendent John Parfet would name another mine "Dollie" after his daughter.

The Greenwood Concentrator was put into operation on November 15th, 1882 at a cost of more than 50,000. It ran day and night and during the first few days in operation, was fed ore from the Cleve and Franklin mines. Supt. John Parfet claims that the ores from the Cleve and Franklin are among some of the hardest ores to concentrate. The Fort Scott Machine and Foundry Company furnished the machinery for the concentrator which was designed by Prof. Fred Stivolinska who oversaw the installion of equipment. This concentrator had the ability to run on steam or water power. By a system of pipes leading from from the main ditch a fall of water is obtained at the works of 289 vertical feet, and the overshot wheel upon which it falls is turned at the rate of 1,700 revolutions per minute, which is geared down to 150 revolutions at the main shaft, which turns the entire machinery. The capacity of the crushers is 200 tons of ore every 24 hours. The ore is transported from the mine, three miles above, over the tramway in small cars, which are run down the grade in trains of thirteen cars each, the grade being sufficient to run them down without power, under the skillful management of six brakemen who are very expert in handling their brakes according to the variations in the grade. The empty cars are hauled back to the mine by mules or horses, one horse being required for each car.

The equipment at Greenwood sold in July of 1903 to the Capitalists who had recently purchased the the U.S. Grant Mine near Virginia City. The plant would be brought to Alder Gulch. The Plant was equipped with Wilfrey tables. crushers, and a complete cyaniding plant which is what the company was after when purchasing the equipment. The equipment was not the original concentration workings installed at Greenwood in 1882. It was installed by the Greenwood Mining and Milling Company as part of improvements in 1899 and included: modern high speed rolls, automatic sizers, Bartlett and Woodbury tables. The power was furnished by a 15-inch double leffel and a four-foot Pelton water wheel. The mill was lighted by electricity. Constructed under the supervision of Thomas White Fisher, a millwright of large experience. The plant was furnished by the Colorado Iron Works of Denver. The Greenwood Mining and Milling Company was leasing the property to work the immense mining dumps of the Hecla Company. Company officials included: D.T. Haskett "President", Charles S. Eltinge "Secretary", Charles A. Harvery of Melrose, "Treasurer".